KK Solutions Ceramic Strip heater provides the ability to withstand higher temperatures . kk Solution Strip heaters, often considered component heaters, are a simple way of using surface area to transfer heat effectively. A fairly inexpensive way of heating surfaces or small areas, strip heaters are an excellent solution to meet any budget. If strip heaters are used as a radiant heater, they have can have fins to maximize surface area and heat transfer to the air.

Our Ceramic Strip Heaters are dependable and reliable flat heating elements – designed to provide efficient heat to flat surfaces from common to industrial applications. The seamless sheath design of Ceramic Strip Heaters makes them ‘dimensionally’ stable in milled slots.

Construction

Ceramic Strip Heaters are constructed with ceramic insulation that quickly conducts heat from the resistance wire to the sheath resulting in low internal temperatures and long heater life in the most demanding applications. Precise placement of the resistance wire provides uniform sheath temperature across the width and along the entire heated length. This is an extremely rugged construction capable of high temperatures and high watt densities.

The inner construction consists of wound nichrome resistance coil. The inner flexible wire is strung through ceramic insulator pieces. The coils are attached to the screw terminals, or high temperature lead wires, for a positive connection. MgO (magnesium oxide) is used to fill and pack open areas surrounding the coils. The MgO material helps increase the elements thermal conductivity and dielectric strength.

ADVANTAGES

- High heat transfer rates and fast heat up

- Ceramic construction for higher temperatures

- Long life

- Large selection of lengths, sizes and terminations

- Low expansion characteristics

- Distributed wattage available

MOUNTING SUGGESTIONS

Ceramic Strip heaters must be clamped securely along a smooth metal surface (along their complete length). When a Ceramic Strip Heater is supported by mounting tabs, ensure that the terminal is secured firmly, and that the opposite end remains loose to allow for expansion. Do not over-tighten nuts when installing, as over-torquing terminals will create internal heater damage.

- Ovens

- Hot Plates

- Dropping resistors

- Dies

- Molds

- Drying

- Melting

- Baking

- Incubators

- Platens

- Food Warmers

- Welding Preheating

- Air Heating

- Sealing Bars

- Thermoforming

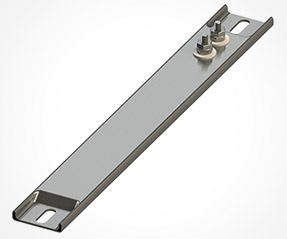

HORIZONTAL POST TERMINALS

The post terminals for this Ceramic Strip heater style are placed on the same end. Optional mounting tabs can added at both heater ends. The Post Terminals come with Ceramic Protection Cap.

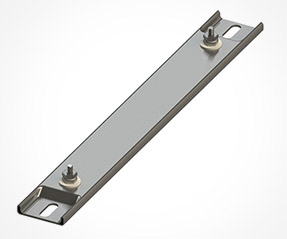

VERTICAL POST TERMINALS

Terminal posts are placed tandem on one end of this strip heater along the center line with mounting tabs at both ends. Optional mounting tabs can added at both heater ends. The Post Terminals come with Ceramic Protection Cap.

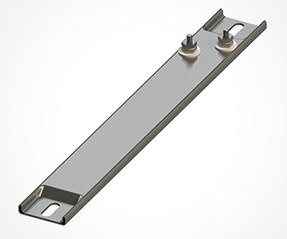

POST TERMINALS AT OPPOSITE ENDS

The terminals on this strip heater style are mounted on opposite ends of the sheath. Optional mounting tabs can added at both heater ends. The Post Terminals come with Ceramic Protection Cap.

OFFSET POST TERMINALS

The terminals on this style strip heater are placed offset at one end of the heater. Optional mounting tabs can added at both heater ends. The Post Terminals come with Ceramic Protection Cap.

HIGH TEMPERATURE QUICK DISCONNECT PLUG

This Ceramic Strip heater with a High Temperature Quick Disconnect Plug assembly enables a quick disconnect from high temperatures.

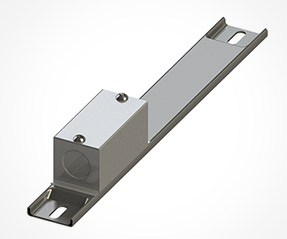

METALLIC TERMINAL BOX

The metallic terminal box style provides beneficial terminal protection against spill leakage, and grounding or short circuiting damage.